-40%

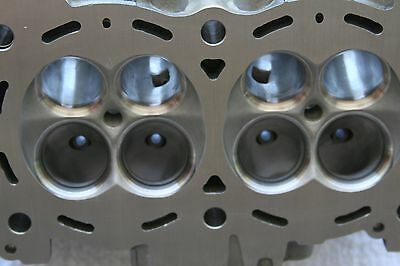

Polaris RZR XP 900 or 1000 CNC race valve job standard size or big valves.

$ 105.6

- Description

- Size Guide

Description

You are buying a race valve job for a Polaris RZR 900 or 1000.This is for you sending me your head to be machined

. If you do not understand this, then do not purchase this service. I use a Newen CNC Contour fixed turning valve machine. This machine is the best machine in the industry to date. I will soda blast or glass bead your head. Then it gets a CNC race valve job that will flow way higher numbers than stock. Then it gets surfaced, cleaned and sent back in perfect condition. If you need parts I have everything you need. I can cut the head for any size valves you want. Plus 1mm or 2 mm over no problem. I do a lot of these heads for race teams and I have been in the industry for over 22 years so I know what works and what doesn't. I also can port the head for any application if needed for an additional fee. Please e-mail me with any questions Thanks

I see people advertising valve jobs on here using old school Serdi and other form tool cutter machines. Those machines are dinosaurs in todays standards. Please research and you will see the tolerances needed to do a perfect valve job just can't be done with a form tool cutter machine. I have had them all and no machine can compare with the Newen platform.

New engines, much tighter tolerances, new valve seat materials, new regulations, tighter pollution controls, the ever growing need for optimum combustion and power, much needed fuel economies, without forgetting skyrocketing labor costs, are all significant contributing factors to the development of a new radical solution and the reasons why old fashioned was to work on cylinder heads had to be revolutionized.

Over the past two decades, OEM specifications have evolved tremendously, tolerances have tightened exponentially and professional engine builders and rebuilders, ill tooled and out of synch with OEM's technologies, have begun to lose market share, unable to meet the new technical requirements set by large engine manufacturers around the world.

Engine re-conditioners provide a service to their own customers. This service is justified only in so far as it meets the technical requirements of the end user and justifies the investment in the repair. Today, engine reconditioners must regain market share.

FIXED-TURNING® is the tool to help them do it.

An implacable precision

Good enough no longer is! Computers, software, motion controls, precision components, and countless other technological advances are all compelling reasons why the methods of yesterday are no longer acceptable.

Imagine a system so simple and so reliable that the nature and/or composition of a valve seat material, its hardness level (soft or hard), the desired shape..., are no longer relevant.

This is what FIXED-TURNING® is all about!

A breakthrough technology protected by multiple international patents...

...a golden opportunity!

Over a dozen international patents and other pending applications protect this unique technology. FIXED-TURNING® isn't a new machine, it is not an updated equipment, it is a breakthrough technology, an actual replacement technology that allows the common engine builders and rebuilders to duplicate the most complex geometries manufactured bo OEMs today and/or to imagine and generate even more optimized shapes expected and demanded by heir own customers.

Beyond precision, beyond mere user friendliness and added productivity, FIXED-TURNING® is the equivalent of thousands of custom form tools, all permanently packaged in one simple and very affordable machine.

A breakthrough technology sought after by OEMs around the world...

...the ultimate validation!

Manufacturing processes have been revolutionized by computers, software and other new technologies. More than ever before, industrial revolutions succeed one another, forcing aftermarket service suppliers to adapt at the same pace.

OEMs constantly use new materials, optimize designs thereby adding to the difficulty, multiply cylinder head models and shapes at a rate never seen before, while tightening machining specifications.

New designs bring new manufacturing challenges to the OEM themselves and many are already specifying recessing as the only acceptable machining method to meet their new and future specifications. FIXED-TURNING®, machining by interpolation of axes, is the most advanced form of recessing. FIXED-TURNING® meets and exceeds every single OEM specifications. With NEWEN's FIXED-TURNING®, OEMs gain flexibility, cut tooling costs, improve geometric qualities, can machine shapes otherwise impossible to achieve.

By the same token, FIXED-TURNING® is the opportunity for engine builders and rebuilders to close the gap between OEMs, the manufacturing world, and the aftermarket service industry. It is the ultimate technology to reclaim their place in the industry and to regain market share against the OEMs themselves.

The widest range of single point equipment for valve seat and valve guide machining, for diameters ranging from 13mm (.50") to 200mm+ (7.87"+) and beyond

NEWEN's FIXED-TURINING® range of products includes the CONTOUR-BB™, the CONTOUR-BB-CS™, the CONTOUR™, the CONTOUR-CS™, the EPOC™, the EPOC-CS™, the EPOC-XL™, the NC6-RCC™, the NC6-RR™ as well as production spindles for transfer lines, high velocity machining centers or rotary transfer equipment.

The NEWEN FIXED-TURNING® range stands as the most comprehensive range of machines dedicated to precision valve seat machining. From 13 mm (.50") to 200mm+ (7.87"+) and beyond, the system guaranties circularities within 3 microns (.00012").

A proven technology with an impeccable track record...

...some of our references around the world

With hundreds of machines now in service around the world in companies as varied as one man shops, small to medium machine shops, production rebuilders, tier 1 suppliers, OEM facilities but also motorsport teams, industrial shops, etc... The technology has passed everybody's tests with flying colors. The reliability is second to none, the precision unparalleled, the flexibility simply amazing.

BMW, Renault, Ford, Cummins, Waukesha-Dresser, PSA Peugeot Citroen, Teledyne Continental Motors, Textron Lycoming, S&S Cycle, Mecachrome, Air Flow Research, Sisu Diesel, Hendrick Motorsport, Dale Earnhardt Inc, BAE, Warren Johnson Enterprises, Ernie Elliot Racing, Arrington Engines, Robert Yates Racing, Penske Jasper, Yamato Engines, Bill Davis Racing, TRD, Roush & Yates, Satriano Competicion, Harrop Engineering, Paul Morris Motorsport...to name a few without forgetting the vast majority of our small shop customers who, like the more visible companies, have opted for excellence and have redefined their business each in their respective geographical area.