-40%

Marine Grade Heat Shrink Tubing Sleeves 3:1 Ratio Adhesive Glue Lined Heavy Wall

$ 4.46

- Description

- Size Guide

Description

Specifications:Automotive & Marine Grade

Flame Resistant Outer Material / Flame Retardant Inner Lining

Working Temperature Range: -49°F to +249°F

Tensile strength: 10.4Mpa

Dielectric strength: 15 kV / mm

Flammability: Flame Retardant

Material: Polyolefin w/Glue

Color: Black, Red, Clear, Yellow, Blue, Green

Inner Diameter(ID): 1/4",3/8",1/2",5/8",3/4",1",2"

Shrink Ratio: 3:1 (Shrinks to 1/3 of its original diameter)

Length: 3ft,10ft,15ft,18ft,22ft,25ft

Features:

[Safety and Environmental Protection] Wonderful heat-shrinkable tubes are UL and CSA certified, RoHS compliant, free of for maldehyde (HCHO), heavy metals and other harmful substances protecting you and your family from toxins.

[The rubber liner has good sealing performance] Our heat-shrinkable tube has the advantages of good electrical insulation, good sealing, corrosion resistance and high temperature resistance. Anti-aging, tough, not easy to break.

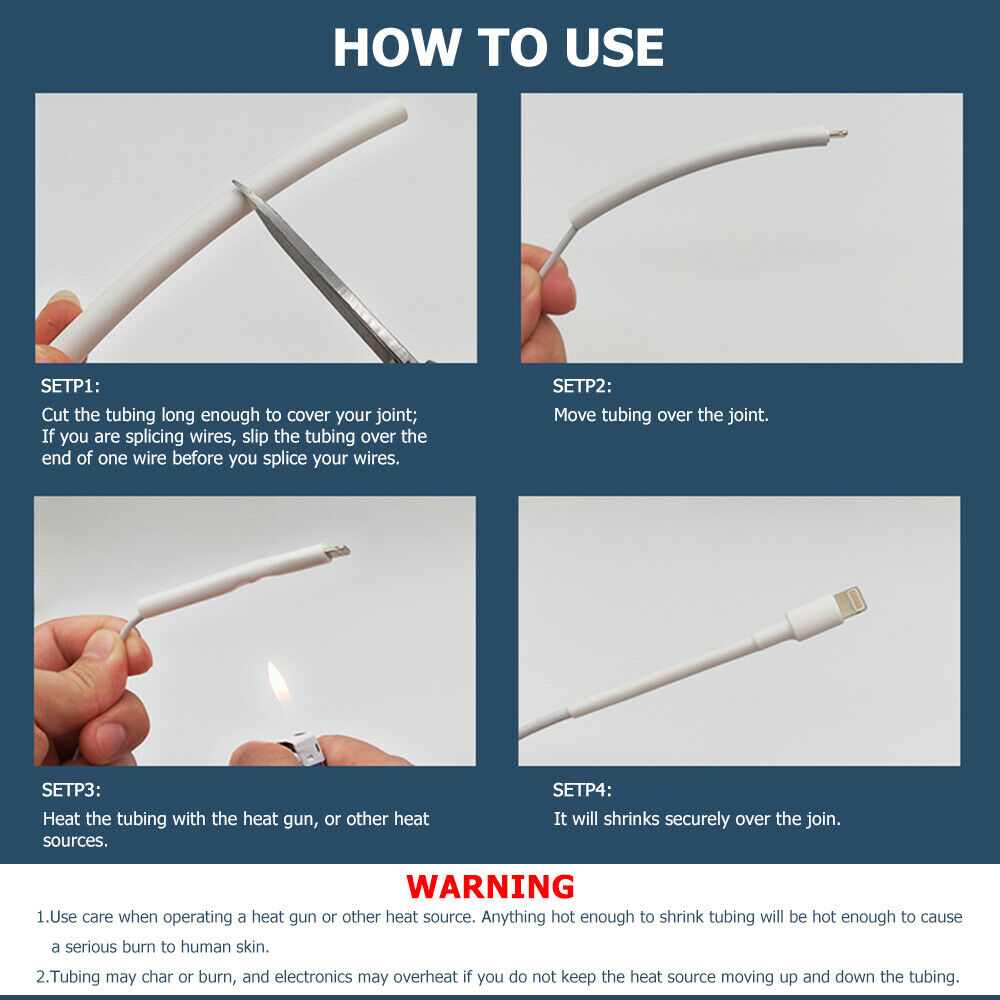

[Easy and fast] You only need to heat it evenly with a hot air blower or a candle to make it shrink. It is a 3:1 heat shrink ratio and will shrink to the original 1/3.

[Versatile and DIY Helper] High-quality heat shrink tubing, they can be used for solder joint protection, group of lines marking, resistance electric capacity reason protection etc. Note: Make sure temperature of your heat gun is up to 212℉(Fahrenheit), then glue inside will soften and seal the connection.

[Great Advantages ] Our heat-shrinkable tube are with glue lined which has the advantages of good electrical insulation, good sealing, corrosion resistance and high temperature resistance. Anti-aging, tough, not easy to break.

[A wide range of applications] Shrink tube are mainly used for industrial, ship, wire links, anti-rust and anti-corrosion protection of solder joints, and audio and electrical DIY. Wire ends, harnesses, electronics protection and insulation treatment, fitness equipment parts and steel structure surface protection and so on.

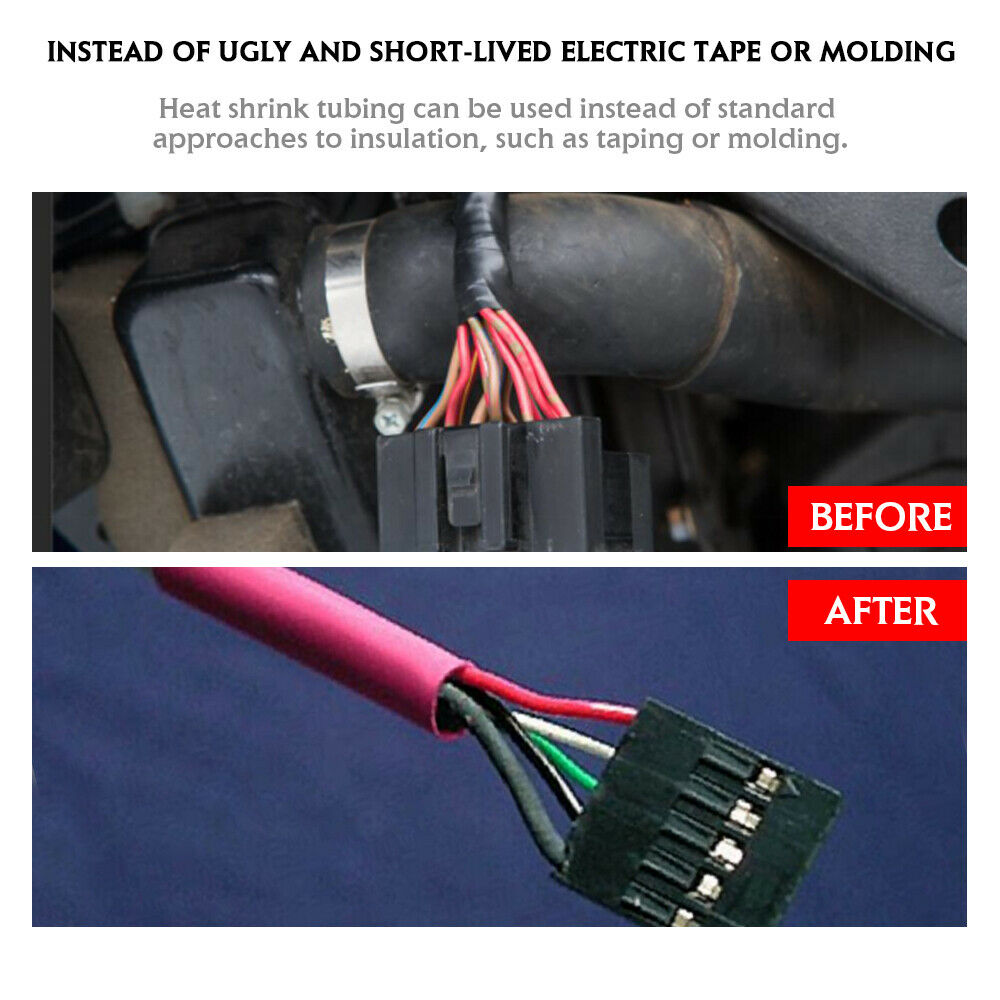

Description

Dual wall heat shrinkable tubing is a 3:1 shrink ratio, flexible tubing, offering the advantages of integral, adhesive-lined construction. The tubing is made from flame retardant, flexible cross-linked polyolefin with an internal layer of excellent hot melt adhesive. The heat-shrinkable outer wall is durable, while maintaining the high flow and excellent adhesion of the inner sealant liner. When heated in excess of 125ºC (257ºF), the tubing rapidly shrinks to a skintight fit, forcing the melted adhesive lining to flow and cover the underlying surface. The adhesive forms a flexible bond with a wide variety of rubbers, plastics and metals. Upon cooling, the adhesive solidifies, forming a permanent, non-drying, flexible and water resistant barrier.

Applications

Dual wall adhesive heat shrink tubing offers excellent environmental protection for electronic components, wire splices, wire bundles and harness breakouts. Automotive, truck and marine wiring splices and harness breakouts are quickly and easily protected from harsh environments.

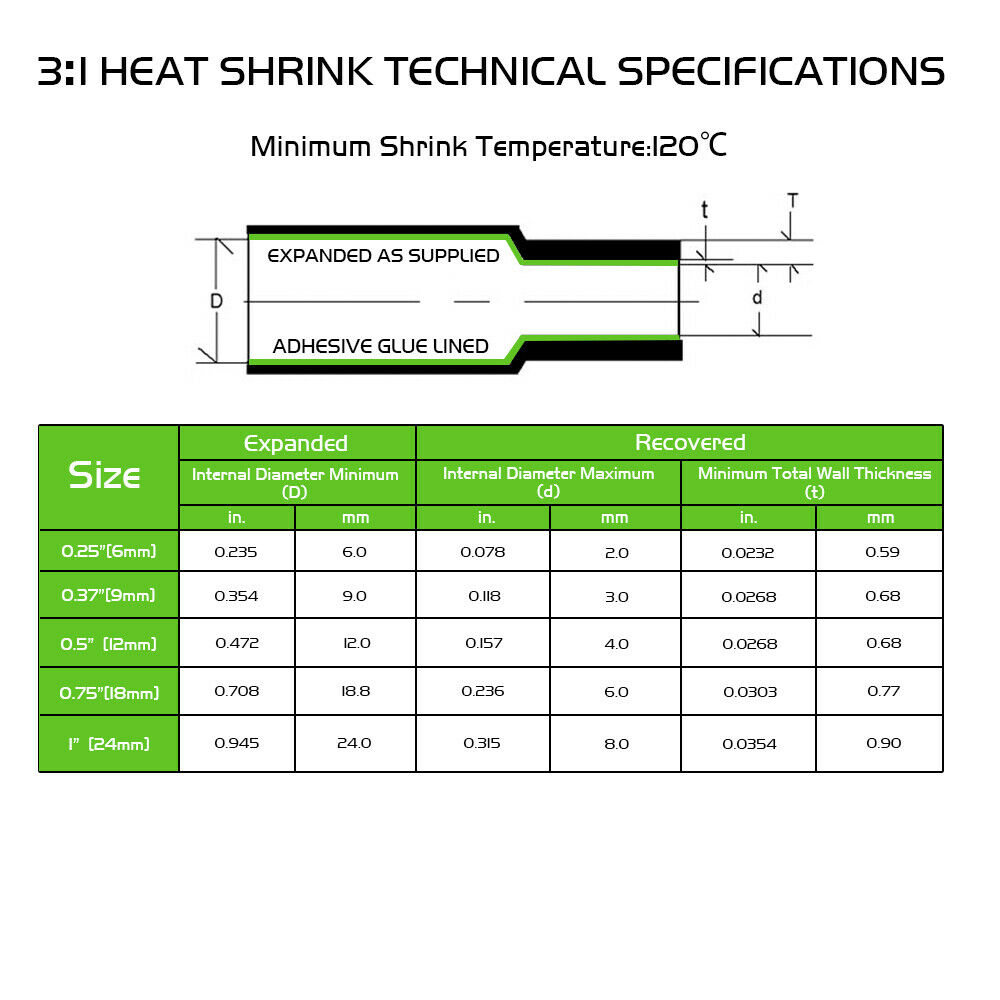

Shrink Ratio

Our dual wall heat shrink tubing has a 3:1 shrink ratio. When freely recovered, the tubing will shrink 33% of its as-supplied diameter. The recovered wall thickness of the tubing is proportional to the degree of recovery. The continuous operating temperature range is from -45ºC (-49ºF) to 125ºC (257ºF), with a shrinking temperature minimum of 125ºC (257ºF).

Sizes and Dimensions

Size

(Nominal) Inch

Wire Range Best Fit Recommended

Expanded I.D.

(Minimum)

Recovered I.D.

(Maximum)

Total Recovered

Wall Thickness

(Nominal)

Meltable

Recovered Wall

Thickness

Inch

(mm)

Inch

(mm)

Inch

(mm)

Inch

(mm)

1/4

18 to 10 AWG

0.250

(6,35)

0.080

(2,03)

0.040

(1,02)

0.020

(0,51)

3/8

12 to 6 AWG

0.375

(9,53)

0.120

(3,05)

0.055

(1,40)

0.025

(0,62)

1/2

8 to 4 AWG

0.500

(12,70)

0.160

(4,06)

0.070

(1,78)

0.030

(0,76)

3/4

4 to 2/0 AWG

0.750

(19,05)

0.250

(6,35)

0.085

(2,16)

0.035

(0,89)

1

2 to 4/0 AWG

1.000

(25,40)

0.320

(8,13)

0.100

(2,54)

0.040

(1,02)