-40%

Flawed, 3M Heat Shrink Tubing, FP301, 1.5" 1-1/2 diameter, Clear, One 48" piece

$ 1.58

- Description

- Size Guide

Description

Heat Shrink, 3M, FP301Flawed - Blemished -Tarnished

Clear, 1.5" diameter

(Quantity: one 48" piece)

But if you're not sure you want to give this flawed product a try, instead please go ahead and buy the regular non-blemished product at this link:

FP301 Clear 1.5" Heat Shrink

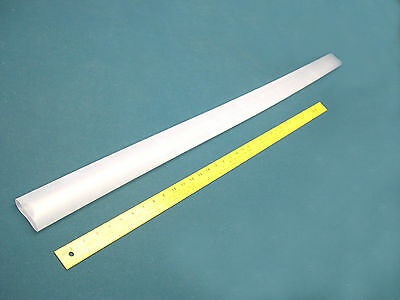

The non-flawed piece is on top; the flawed, blemished piece is on bottom.

This photo shows about the middle 10" of the two 48" pieces. You can see that the bottom piece is not quite as clear. This is about as much difference between the flawed and non-flawed as I could find.

The non-flawed piece is on top; the flawed, blemished piece is on bottom.

This photo shows the right end of the two pieces. Other than the color (clearness), everything else appears to be about the same.

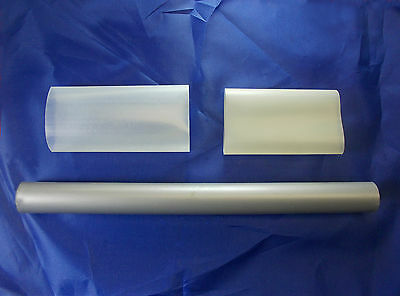

This photo shows two short samples just before they're shrunk onto a 12" bar.

The non-flawed piece is on the left; the flawed, blemished piece is on the right.

This photo shows the non-flawed (left) and flawed (right) samples after they've been shrunk onto the metal bar. Their diameter is now 1.0" and everything is about the same except that the flawed piece is still slightly yellowish.

Here's a closeup. The regular piece is on the left; the flawed, blemished piece is on the right.

The remainder of this description describes the non-flawed 3M Heat Shrink in general and is copied directly from the descriptions of both those producs, including both the 3M Red and Clear 3M FP301 1.5" diameter products.

Many of the photos below are used to show the characteristics and usage of both these 3M FP301 products, including both the red and clear, which are pretty much identical in specification. But p

lease note that the photos showing red below are for purposes of illustration only; this sale is for the Clear/Flawed Heat Shrink only.

3M™ world-class quality Heat Shrink Tubing FP-301 offers an outstanding balance of electrical, physical and chemical properties for a wide variety of industrial and military applications. Rated for 135°C continuous operation, all FP-301 tubing is split resistant, mechanically tough, easily marked and resists cold flow.

FP-301 tubing is typically used as a shrink-fit electrical insulation over cable splices and terminations. It is also used for lightweight wire harness covering, wire marking, wire bundling, component packaging and fire-resistant covering.

FP-301 tubing is rated for continuous operation at -55°C (-67°F) to 135°C (275°F), and is designed to withstand elevated temperatures to 300°C (572°F) for short periods.

The combination of desirable electrical, thermal, water resistance, corrosion resistance, size, etc. makes it applicable to many applications in which the user may not at first consider heat shrink.

Minimum shrink temperature for all FP-301 tubing is 100°C (212°F).

FP-301 tubing has a 2:1 shrink ratio ― i.e., whenever the 1.5" diameter product is heated without opposition, so that it is shrunk as far as it is able to shrink, it will have shrunk to .75".

Manufacturer:

3M

Part Number:

FP301 1.5 Clear

Material:

Flexible Polyolefin

Color:

Clear

Length:

One 48" Strip

Unheated Diameter:

1.5"

Minimum Heated Diameter:

.75"

Shrink Ratio:

2:1

Elongation (Breaking Point):

400%

Minimum Shrink Temperature:

100

°C

Minimum Shrink Temperature:

212

°F

Operating Temperature:

-55°C to +135°C Degrees

Operating Temperature:

-67°F to +275°C Degrees

Dielectric Strength:

900 volts

Tensile Strength:

2400 PSI

Non-Corrosive:

Yes

Mil Spec:

AMS-DTL-23053/5, Class 1

((((( Note ― Red heat shrink shown below for purposes of illustration only )))))

In case you're unfamiliar with this product ― especially as it is used in the larger sizes ― the following 11 photos should give you the idea. They show (for the purpose of illustration only) a piece of Red FP301 1.5" heat shrink (HS) placed on a handlebar grip of my wife's bicycle.

The first two photos show a 5" piece of the Red HS cut off and placed loosely on the handlebar grip.

After pushing the HS fully on to the handlebar grip, I shrunk it down with my heat gun. You'll need a lot of heat to apply this product (212° F, to be exact), so you can't do it with just any old hair dryer. Once the HS was shrunk, I trimmed the ends with a razor knife. The next 8 photographs show the result. (Please note that the camera's flash makes the first photo look more pink than red.)

Notice the detail you can see in some of the photos. There is an oval shaped emblem and some horizontal stripes on the grip that you can make out in some of the photos. With the clear HS that emblem should be fully visible,

((((( Note ― Red heat shrink shown for purposes of illustration only )))))

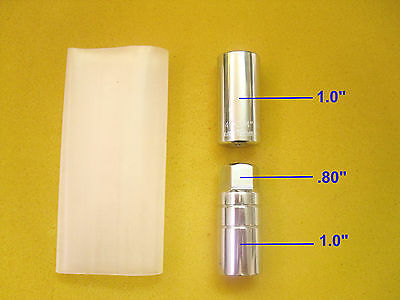

The three photos below show the heat shrink (HS) applied to sockets of different diameters. The outer diameters of each of the sockets are shown. The first (yellow-border) photo shows the sockets and the FP301 1.5" HS before it is heated. After heating the HS with a heat gun to more than 212° F for about 3 minutes each, and trimming the ends off, the results are shown in the middle and lower photos (blue and green borders).

As you can see, the HS did a good job on the entire range of steel diameters, with the exception of the .70" socket, which is below the specification of the minimum diameter to which the 1.5" HS is able to shrink, which is .75". To illustrate this effect, we've pulled the .70" socket out a little bit in the lower photo to help show that it's loose. We would be unable to do this with any of the other socket diameters, because the HS is holding them too tightly to pull the sockets out.

The conclusion that I draw from both the bicycle and socket tests is that the FP301 1.5" HS will work with any diameter in the range from .8" up to about 1.4", with the ideal diameters being in the ranges of about .8" to 1.3". Also, I've found that it takes a bit of practice to get a smooth fit and shrinkage.

We are often asked "How clear is it?" Please use the following test as a guide. The two photos below show the clear 1.5" heat shrink (HS) applied to two sockets with an outer diameter of 1.0" each and a 0.80" section between. With the HS fully applied, as you can see, you can still read the socket labels as well as the circular grooves on the lower socket. So, in answer to the question, we would say, "It's kind of a frosty clear, but clear enough to see details and read letters."

I have a truckload of heat shrink ― different sizes (mostly 1.5", 1.0", and .75"); colors, (mostly black, white, red and clear); and types (including Thick Wall). If you'd like to see them, just click the green button below.

Click here to see my

Heat Shrink

Click here to

visit my store (list view)

Click here to

visit my store (gallery view)

Click here to

save me as a seller